Our Meltblown Nonwovens

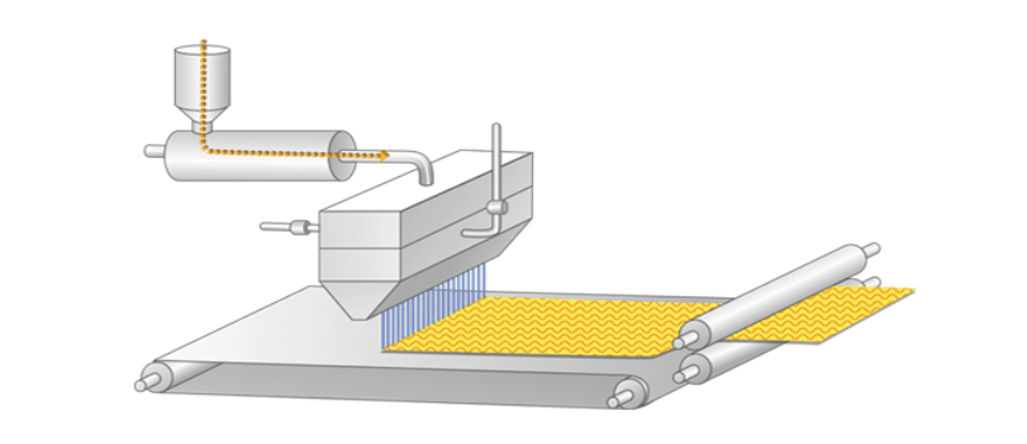

Meltblown Process

The melted resin is pushed out through a nozzle and simultaneously stretched by hot air to form ultrafine fibers while welding them together to make nonwoven fabrics.

We can produce nonwoven fabrics from a wide variety of thermoplastic polymers not only polypropylene but SEPTON™, a Kuraray group thermoplastic elastomer, and thermoplastic polyurethane (TPU).

Particularly special one is VECRUS™ made from liquid crystal polymer (LCP).

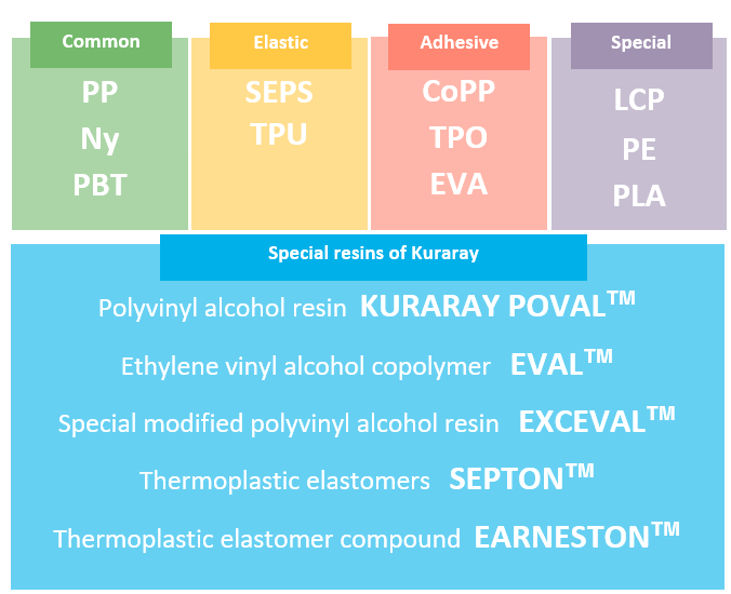

Raw Materials

We have taken advantage of the nonwoven manufacturing know-how we have cultivated over many years and our strength as a Kuraray group company that have many special resins.

We are able to produce meltblown nonwovens from polypropylene, nylon, and polybutylene terephthalate, which are common raw materials used in the meltblown process, as well as from polyurethane and olefinic thermoplastic elastomers, polyethylene, liquid crystal polymers (LCP), polylactic acid, etc.

Originality of Kuraray

We will harness the Kuraray Group's technological capability to open up a new world of nonwovens.

POINT01 Special materials

We can produce special nonwovens using Kuraray's proprietary materials.

For example, we can manufacture high-functional nonwoven fabrics that take advantage of the characteristics of raw material resins such as SEPTON™ thermoplastic elastomer with excellent stretchability, or Polyarylate resin with its high strength and superior heat resistance.

SEPTON™ is trademarks of Kuraray's special resins.

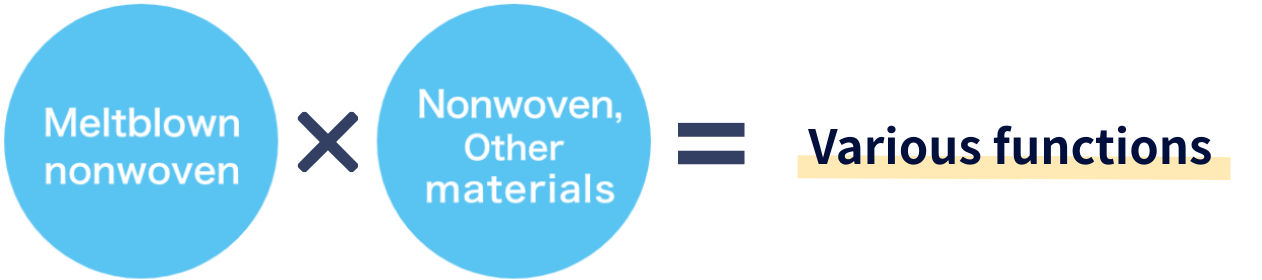

POINT02 Combining technology

By combining nonwovens that have other properties each, or with other materials, Various functions can be added to our nonwovens.